Maintenance, not repair: What is already possible in predictive maintenance today

Finding the ideal time for maintenance poses a major challenge for operators of mobile working machines. How can unscheduled downtimes be eliminated and operational time maximized? In the off-highway sector, a wide range of condition monitoring solutions are available for this purpose. But this is just the beginning. Using the ‘digital twin’ concept, companies are working on solutions that will take predictive maintenance to a new level.

On construction sites or in a field, the spectrum of modern off-highway vehicles is enormous and the range of drive types, encompassing diesel, gas, electric or hydrogen, is more diverse than ever before. Nevertheless, all mobile working machines, irrespective of their differences in terms of their application and function, have one thing in common: they push the limits of their performance capacity and have to meet the highest standards of efficiency and operating safety, even under the harshest of environmental conditions. The consequences of unexpected mechanical, hydraulic, electrical or electronic system malfunctions can prove costly and simply reacting, by carrying out repairs once a failure has occurred, is not the best solution. Additionally, machine manufacturers find that predictive maintenance is an ideal tool for reducing service and maintenance costs, particularly during the warranty period.

Smart sensors for machine data collection

“Condition monitoring” and “predictive maintenance” are now frequent terms used connection with current and future application scenarios relating to the digitalization and automation of mobile machinery. The advantages of these technologies are readily apparent: early detection of faults, minimisation of unscheduled downtime and the support for proactive machine maintenance. For instance, one interesting case concerns the drivetrain and the question why a drive shaft is showing signs of wear. Is this just normal wear and tear or is the drive shaft misaligned or otherwise subject to excessive strain, resulting in premature wearing?

Such deep insights into the workings of an off-highway machine, tracking down technical defects before they occur, require precise data as well as a detailed understanding of the respective contexts. Smart sensors that measure the load at key points provide the required data, and indeed, mobile machinery is today equipped with multiple sensors and control units, which means measurement capacity has never been greater. The optimum time for a repair, however, can only be determined through intelligently combining sensors and real-time data analysis, using algorithms to predict what sort of damage will occur when, on the basis of current and historic data.

The ‘intelligent’ drive shaft in the powertrain

New developments, to be presented at Systems & Components in Hanover, will improve and simplify condition monitoring for powertrains. These developments hold particular promise for the reliability of agricultural machinery, important when considering the relatively short harvesting periods – around eight weeks a year for cereals, for instance. During this period, combine harvesters and tractors must operate without malfunctions to prevent bottlenecks throughout the entire agricultural process chain. Smart sensors enable machine control to adapt optimally to the soil conditions or to the harvested crop as well as operating at the optimum load point.

The solutions and services that will be on show at the trade fair grounds will enable operators of mobile working machines to check the condition of components within the drive train at any time and to plan maintenance based on actual needs rather than relying on fixed time intervals or running hours. The maintenance solutions from the Walterscheid Powertrain Group, for example, integrate smart sensors directly into critical drive shaft components, which transfer system parameters, such as torque, rotational speed, deflection angle and temperatures during operation in real time. This data provides information on the drive shaft load to help detect wear early on.

The driver can read out the information from such an intelligent drive shaft in the cockpit and, if the on-board computer notes any deviations from the norm, an alarm sounds and diagnostic information is displayed.

Monitoring the machinery

In the event of component failure or following an inspection, any required replacement parts can be identified and ordered quickly and easily, thus enabling trouble-free operation of the machinery. The company Zeppelin will be showing how this works in practice with a newly developed fleet management platform, ‘Como’. Every piece of equipment is connected to the system, allowing an operator to visualise the entire fleet, along with event and diagnostic codes for every machine. Any faults that occur in one of the over 50,000 Cat construction machines operating throughout Germany can be decoded and interpreted and any required actions recommended. A complete log of the machine’s event and diagnostic codes is displayed in overview, allowing analysis of frequent codes. If problems arise simultaneously, codes are prioritised and the most important actions noted. Selecting a code directly allows the user to view the details of the construction machine, with its serial number, operating hours and scheduled inspection date. In addition, ‘Como’ can display a map of every machine in the fleet, enabling the technician, equipped with any necessary replacement parts and tools, to quickly locate the faulty machine and get it up and running again.

Into the future with a digital twin

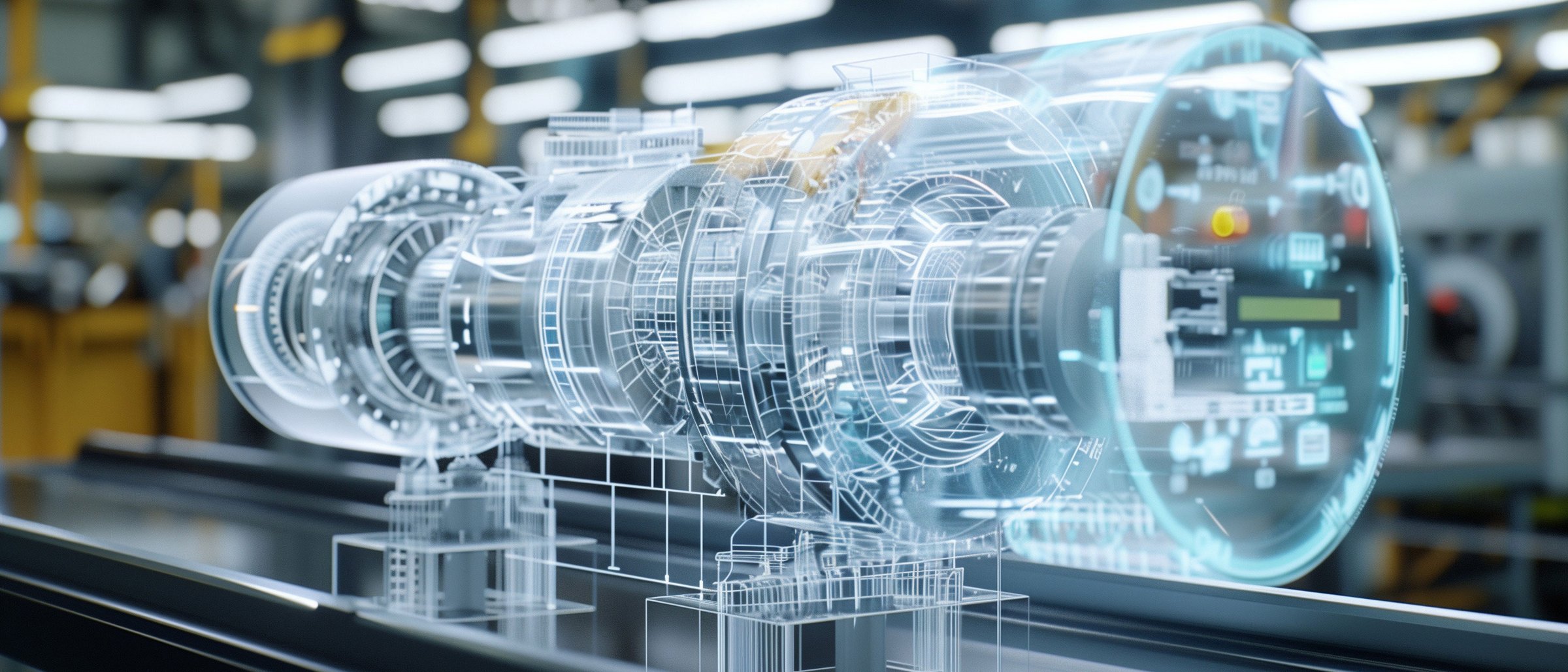

The possible applications of the technology go far beyond a proactive maintenance strategy. ‘Digital twin’, with its digital representation of the machine’s functionality, brings the life cycle of the components into focus. A detailed model receives the real machine’s sensor data in real time and, in the event of damage, the service technicians are able to use the digital twin to analyse the data and more precisely localize the cause of the malfunction.

The concept also allows new service business models to be prototyped in simulation. For instance, information on the real load cycle can be collected and then used to support design engineers and developers in designing new drive shafts or steering systems to cope with real-world loads. While physical prototypes were indispensable in the past, in the future drive train modelling will help to identify critical areas and optimisation potential for products in development. Various technology providers are currently developing such drive train models, which will take predictive maintenance to a new level.