List of Nominees 2023

SYSTEMS & COMPONENTS Trophy

As part of AGRITECHNICA, the DLG awarded the "SYSTEMS & COMPONENTS Trophy - Engineers' Choice" for components and systems. With this trophy, awarded for the third time, the DLG recognized the inventive spirit of the supplier industry along with its great importance to agricultural technology.

The final Trophy winners were selected from a shortlist of 21 "nominees" in a second round, judged by the jury of development engineers from the agricultural machinery manufacturers exhibiting at AGRITECHNICA.

The award ceremony took place at the SYSTEMS & COMPONENTS Expert Stage on 12 November 2023.

Nominees 2023

AEF - Agricultural Industry Electronics Foundation e.V.

Enhanced Road safety for agricultural vehicles

On-road accident of tractors and other self-propelled agricultural machinery are quite rare. However, they always pose a high risk of major damage as well as a danger to the life and limb of those involved in the accident. To minimize accidents, the best approach is to prevent dangerous situations altogether. One effective strategy is the implementation of standardized radio communication for sharing intentions among road users, which can help avoid hazardous situations. For instance, a broken-down vehicle could transmit a warning message that would be displayed in approaching vehicles even before the hazard comes into view. By implementation of Vision Zero into all ag machines that drive on the road, the AEF in close cooperation with Volkswagen and various other car manufacturers aims on eliminating the loss of life caused by on-road accidents.

AGREENCULTURE

AGCbox

Nowadays, most autonomous machines are equipped with bumpers, to stop them in the event of collision. Some use LiDAR, radar, or sensor fusion to scan the environment and stop the machine if necessary. These components are well designed to avoid collisions, but they can never prevent a robot from ending up in a high-risk area, such as a road bordering a field. Known solutions such as boundary wires or physical limits are not applicable to farming in large agricultural areas. The AGCbox of AGREENCULTURE now is the first GNSS-based system that precisely locates the machine and detect when it leaves its work area. Safencing is the world’s first certified geofencing system for off-road applications that fully complies with the Machine Directive 2006/42/CE. With this Safencing function, the AGCbox makes robots truly autonomous and thus overcomes the previous methods of supervision that go against all advantages of robotics.

agroparts LexCom Informationssysteme GmbH

agroparts spare-parts research based on image recognition

Agroparts is one of the world’s biggest multi brand platform for agricultural spare parts. Nevertheless finding the correct spare part may be difficult, especially when especially if the manufacturer has changed supplier parts within different series of the machine. Agroparts has now implementet a spare-parts identification via AI-supported picture recognition to their database. As the complexity of modern machines with thousands of parts and many variants is increasing, pure image recognition is therefore often insufficient and in addition requires usually several reference pictures per item. By combining an backlashing the recognition with information about the exact configuration of the machine and the spare-parts installed, the learning curve of the AI algorithms has been improved significantly.

ARGO-HYTOS GmbH

Return filters with AirEX air separation

A hydraulic tank basically has to be big enough to compensate for the pendulum volume of the system. In reality, however, it is usually dimensioned larger because this means that more oil remains in the reservoir and the dwell time of the oil in the tank increases. Downsizing such tanks could lead to problems, because air within the oil might not be able to outgas naturally. By using return filters with AirEX separation from ARGO-HYTOS a reduction of the tank volume of up to 50 % is possible. The effective AirEX deaerater relys on a 3D-labyrinth structured medium. The flow through this medium leads to mutual and crossing flow paths, which increases the collision probability and also the coalescence of air bubbles. Long story short including other features: small air bubbles are transformed into bigger bubbles that easily leave the oil. Downsizing the oil tanks significantly reduces costs. In addition longer change intevals will be possible saving resources and helping to protect our environment.

BONDIOLI & PAVESI GmbH Deutschland

E.D.I. (Electronic Data Interchange) Driveshaft

It is a fine art to use agricultural machinery as productively as possible without overloading it or causing damage through high and frequent load peaks. With Bondioli & Pavesi’s EDI PTO driveshafts farmers will be provided with real time information on the tractor dashboard regarding driveshaft’s status, the power absorbed by the implement, and predictive maintenance. The sensor system includes information on torque, speed, axial force as well as vibrations and monitors the degree of overlap of the two PTO shaft halves. This gives the possibility of optimizing productivity and maintenance, reducing costs and time of breakdown. If coupled with a self-driving tractor without operator it provides info and warnings to fleet manager.

COBO S.p.A.

VDS - ATX

When it comes to keeping an overview, the operation of machines with large working widths poses major challenges for the operator. In the long term, every element in the field of vision is a nuisance. The new VDS ATX from COBO is a steering column with different functions that for the first time have been combined for the first time in an out-of-the-box component system. The VDS ATX that includes a 7-inch display as well as a keyless system that allows the recognition of the operator through the hand shake of the key and the CPU. This reduces the risk of theft and misuse of the vehicle and allows to automatically remember and configure all the pre-set settings like seat, armrest or display settings, saving time for the operator.

elobau GmbH & Co. KG

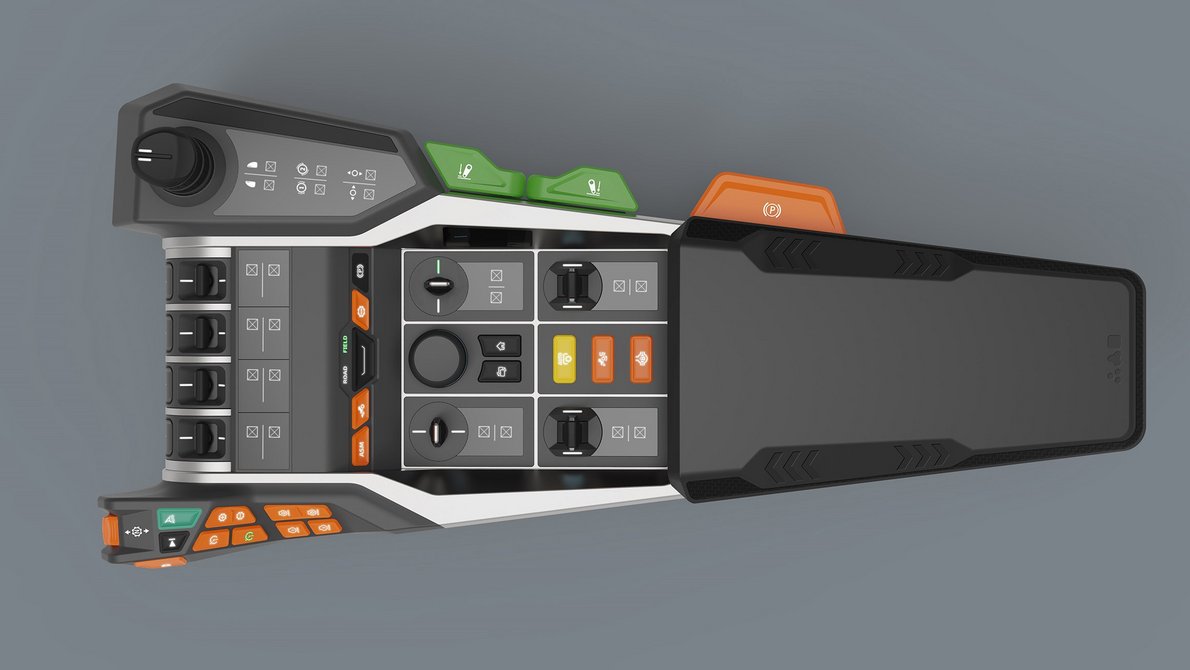

aISA (adaptive Interface Systems in Agricultural tractors)

In cooperation with:

- SAME DEUTZ-FAHR DEUTSCHLAND GmbH

- Competence Center ISOBUS e.V.

The versatile use of tractors not only in agriculture but also in construction, forestry, and the municipal sector requires alternating implements that need to be coupled to the tractor. Each implement has its own requirements concerning its operation. However, today's multi-functional armrests in tractors are mostly static and therefore a compromise solution in ergonomics for alternating operating scenarios.

With the aISA (adaptive Interface Systems in Agricultural tractors) from Elobau an implement can configure haptic controls on a multi-functional armrest in a tractor for the first time. Changes may be assignet to function specific icons and lighting, hiding or changing the base position, changing of the operating characteristics as well as shifting positions to a higer ergonomic rank. The aISA System is based on the ISOBUS Standard, making it easy for tractor or implement manufacturers to integrate.

Fernsteuergeräte Kurt Oelsch GmbH

Lenkjoystick LPR-2515

At current state, steering is mostly done by steering wheels with a significant mechanical setup at a fixed predefined position and interference with the view of the work area. Joysticks are more versatile but actually either show no feedback of the wheel position or are not suitable for road travel. For the first time available as a component, the LPR-2515 from FSG summarizes some already-known features and additionally guarantees the steering ability even if the feedback unit fails. This results in a high safety level, which is required for road approval ("steer-by-wire"). The integration into the driver's workplace improves ergonomics and allows the driver's seat to be turned together with the steering unit. In applications with large steering deflections, significantly fewer arm movements are required, resulting in fatigue-free performance of the task.

iGRAIN Eye-Grain ApS

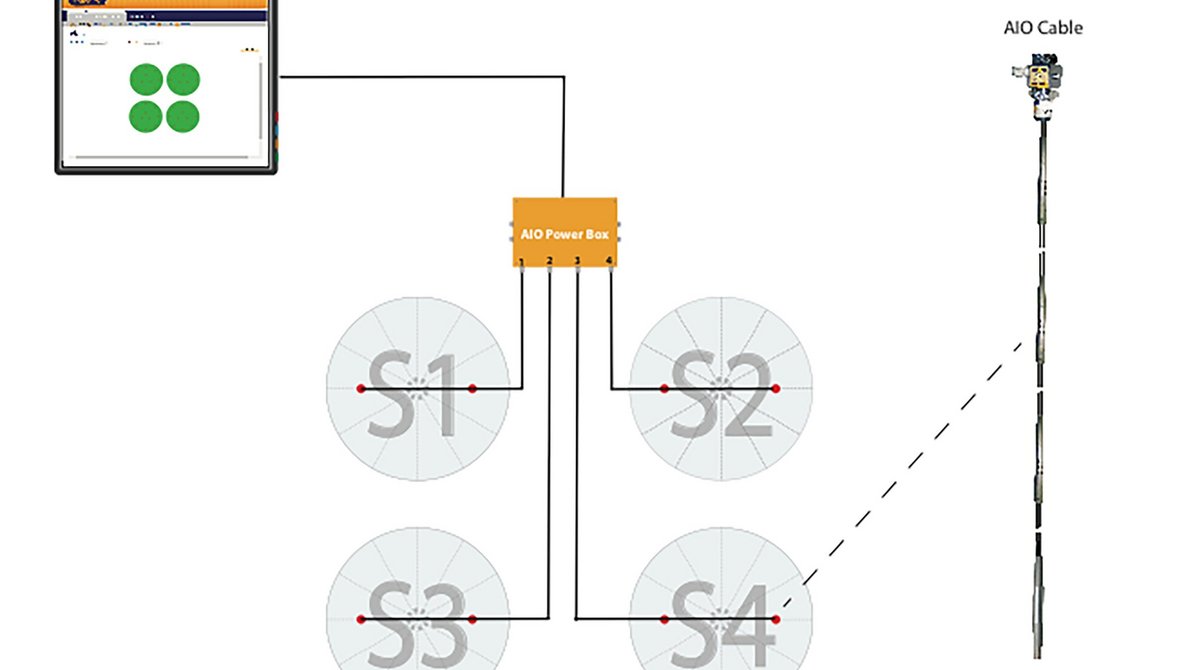

iGRAIN All-In-One Sensor Cable

Grain storage has relied on temperature measurements for 70+ years. Due to the insulating properties of the stored goods, this has the disadvantage that insect or fungal nests are only detected if they are in close proximity to the temperature sensor. Gas analysis has the huge advantage that gasses are flowing freeing in the space between the grain kernel, and as a law of nature gasses are distributed evenly in all directions. Therefore, only a few gas sensors are needed to determine the infestation and the quality of the grain in any grain silo. The iGRAIN All-In-One Sensor Cable combines different gas sensors and thus the ability to sense the current grain quality and control aeration in the most economical way. Based on a complex system of algorithms and using the gas sensors’ input, the current grain quality and moisture ist measured and the user gets a prediction for which time the grain will stay safe during storage in a given silo. This makes grain monitoring easier, more precise, and comprehensive than traditional temperature monitoring and in addition the system is also capable to control the grain aeration process automatically.

Impro Fluidtek Europe Sarl

RE 550 Series

One of the biggest challenges in the installation of hydraulic components is the issue of space. Thus great efforts have been made by many manufacturers to make existing systems smaller and more universally applicable. With the RE 550 series, Impro Fluidtek offers an orbital motor product line presented by Impro Fluidtek, which fits for versatile range of applications, especially for low flow, high pressure applications such as agricultural equipment. Although the component has become 13% lighter, volumetric efficiency during startup has been vastly improved by flexing the balance plate towards the rotor. Smaller size and three bearing options and a flexible customization will allow the motor to be matched to many applications.

IWN GmbH & Co. KG

VariQtire

Common tire pressure control systems (TPCS) either have disadvantages due to their external mounting of the air supply over fenders and mudguards as this widens the vehicle or due to the special technical challenges of an in-axle-integration which is pricy, not retrofittable and up to date prone to failure. VariQtire from IWN is a TPCS developed as a complete package either as stand alone version with own cab-terminal or run via ISOBUS. The system ist based on an internal, axle-encompassing rotary union that is compatible with all common axle sizes and can be retrofitted on any type of tractor without affecting vehicle width. Thus VariQtire offers all the known advantages of tire pressure control towards sustainability, resource conservation and soil portection while overcoming most of the obstacles and weakness common systems.

Lenord, Bauer & Co. GmbH

VarioCODER

Developers of e-drives for industrial and agricultural vehicles are often faced with a dilemma: Either they choose a standard rotor position sensor, which, however, requires complex integration as this sensor type has a satisfactory accuracy but a demand for very low mounting tolerances. In addition these resolvers are sensitive to interference from stray magnetic fields and lack speed stability at shaft rotation speeds beyond 10,000 RPM. The other option might be a customized sensor, which is more expensive and often not robust and accurate enough. With the all-new VarioCODER, Lenord+Bauer offers a customized, zero-series C-pattern within a few weeks. Due to its variable geometry and configurable technical features, it always fits perfectly, has a high stray field immunity, a very short latency and a wide temperature application range. The VarioCODER is ASIL C-capable according to ISO26262 or PL D-capable according to ISO13849 and therefore suitable for safety-relevant applications, including fully autonomous driving.

MOBA Mobile Automation AG

HLC-4000 Radladerwaage

Within wheel loader weighing systems several obstacles may occur. Switching in between different systems may be complicated and not intuitive. Multi-job editing or a even multilingual user interfaces are often not available and most systems lack of real-time data management or cloud connectivity. With the new HLC-4000 weighing system, MOBA Mobile Automation addresses all of these obstacles at once, which leads to a significantly reduced amount of time spent managing and analyzing data and a higher efficiency of work processes as most of the data management can be done automatically. The dynamic weighing system includes Tip-Of-Truck and Tip-Of-Pile functions, an intuitive touch display and a multi-job editing function in multiple languages. The rear view camera improves safety when operating the wheel loader.

Rockinger Agriculture GmbH

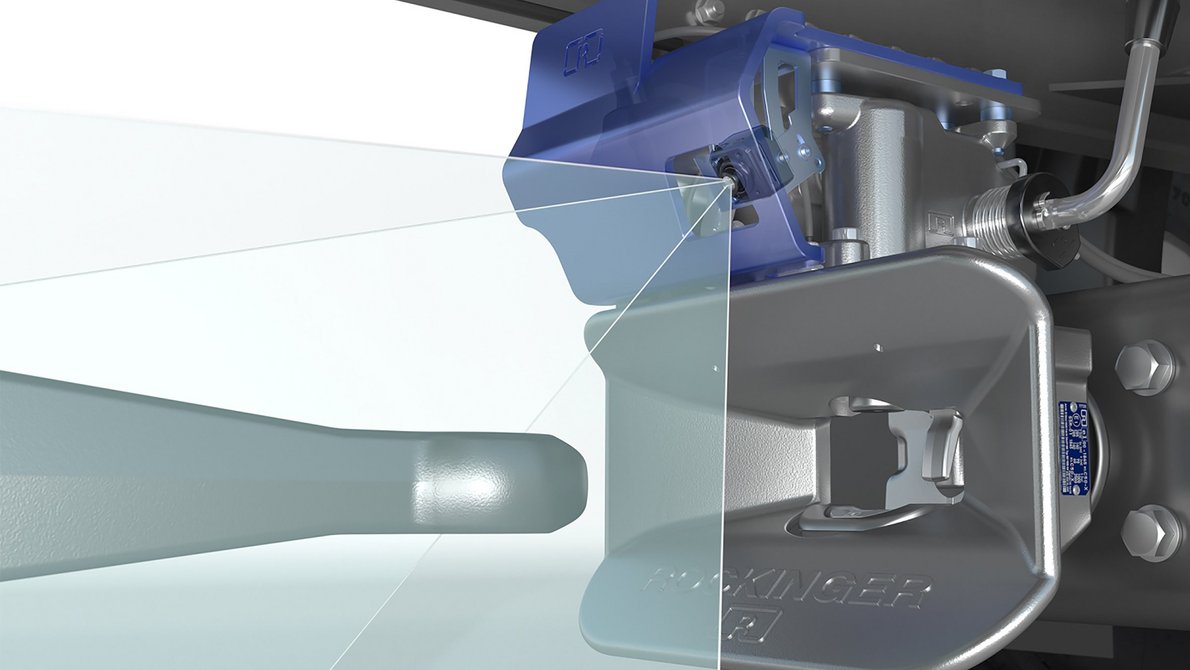

RO845D automatic 50 mm hitch with camera system

Since it all comes down to millimeters, reversing and coupling even for experienced drivers may be a challenge using a standard towing hitch. To deal with that specific problem, the Rockinger RO845D hitch is the first 50 mm automatic towing hitch with an integrated camera system. By using the system, the calibrated camera system captures the towing eye and gives the user spatial orientation during the coupling process. The towing eye can be aimed with the help of the crosshair and the center of the trailer can be approached. Additionally the area for the optimum height of the vehicle to the towing eye is shown using the green auxiliary lines, which in sum marks a significant enhancement of driving comfort as well as safety level.

Rockinger Agriculture GmbH

KS80 Ball hitch with wear insert

Lubrication of a KS80 Ball hitch is necessary, but but the grease magically attracts dirt, which in turn leads to higher wear and tear. By using the Rockinger KS80 Ball hitch with wear insert no further lubrication is necessary. This leads to less wear on the ball 80 and saves up to 8 cartridges of grease per cap per year. The wear insert is easy to replace, there is no need to replace the entire calotte, which makes it a sustainable, environmentally friendly and cost-effective solution.

Rockinger Agriculture GmbH

Ball hitch KS80 with safety sensor

Whoever has ever used a KS80 Ball hitch should be aware that in rare cases it might be not locked correctly, which bears the risk of severe accidents. To check whether the Ball hitch is locked, the driver usually has to stop, get off the tractor and take a look on the coupling. With the Rockinger KS80 Ball hitch with safety sensor the correct locking status of the KS80 ball hitch is shown at the display in the driver cabin. Incorrect operation and the resulting damage of the KS80 hitch and/or the towing vehicle are excluded. The system operates completely wireless including a dirt and water-resistant unit (IP-69-K). Current versions are suitable for heavy duty with 4 t vertical support load and a D value up to 130 kN.

SCHUMACHER GmbH

ARISTA crop lifter with QuickFit system

Traditional crop lifter designs have a catch and an extra locking strap to attach the lifter to the guard. Mounting crop lifters to the guard oder adjusting them relies on lose parts like clips and mostly requires the use of tools such as screwdrivers. The quick-fit system of the all-new ARISTA crop lifter from Schumacher in contrast is based on the simple mechanism of a snap closure with no loose components that allows operators to fit, remove and adjust the lifter without the need of extra tools, which saves time and effort and allows operators to concentrate on combining. Another advantage of the new quick-fit crop lifter is its top-mounted position, i.e. on top of the guard. Thus also in flex combine headers a necessary ground clearance is maintained and the attachment mechanism does not interfere. In summary the operator benefits from the easy-to-use locking bar and the simple and time-saving design of this quick-fit lifter.

Thomas Group

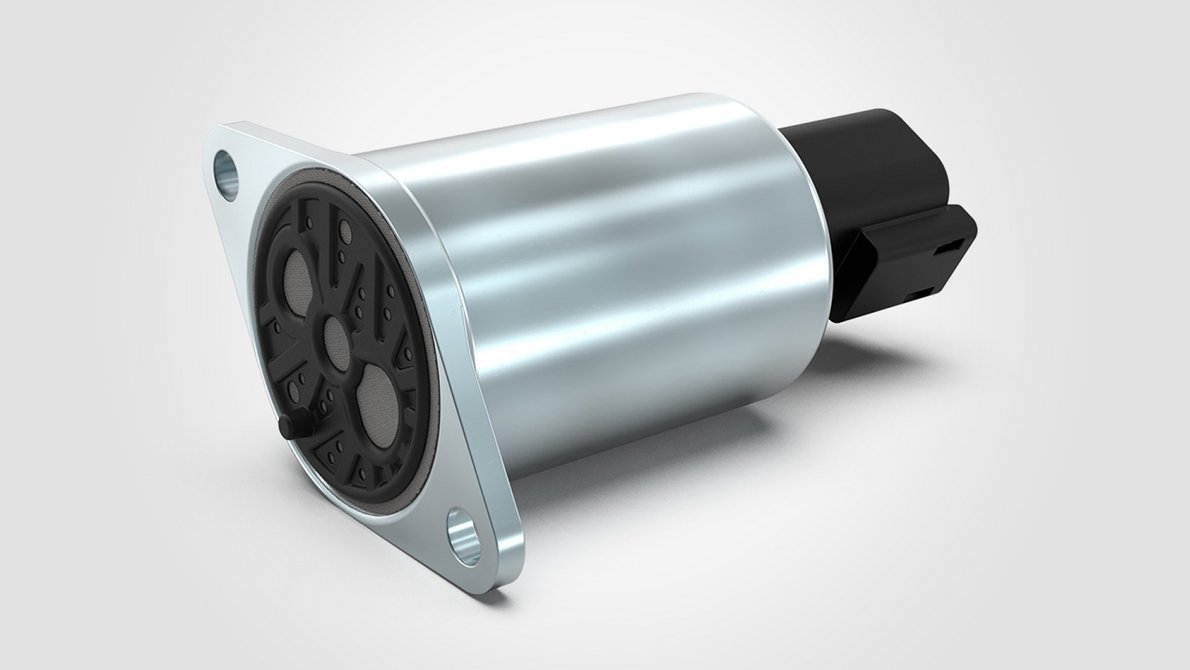

IPH (Integrated Pilot Head)

State of the art valves are usually designed with a protruding valve sleeve and therefore require quite much space for installation. Package is strongly depending on the size of the required valve cavity that, by the way, is also a very complex machining operation. The all-new Integrated Pilot Head IPH from Thomas Group is the only proportional pressure-reducing valve that is ideally suited to compact machinery. All hydraulic functions are contained within the solenoid, without the well-known protruding valve sleeve. This innovative design ensures a compact and space-saving form factor while delivering an impressive performance and a flow rate of 2.5 l/min. Omitting the valve sleeve means: no cavity needs to be drilled for the valve and thus OEMs can reduce the size of their manifold and save material & machining costs.

Ullmanna s.r.o.

AROW

State of the art in weed control involves labor-intensive manual weeding, environmentally damaging chemical herbicides, and bulky, crop-specific mechanical weeders. With the AROW Box, Ullmanna for the first time provides a high-tech component that identifies and targets crops in real-time, providing a chemical-free, environmentally friendly solution for weed control by means of artificial intelligence and machine vision. The system includes advanced features such as visual odometry, innovative lighting for cameras, and depth sensors to ensure optimal operation even under challenging field conditions. The system integrates lighting, cameras, AI and controls as well as a wide compatibility range with diverse machines from numerous manufacturers for both in-row and inter-row weeding.

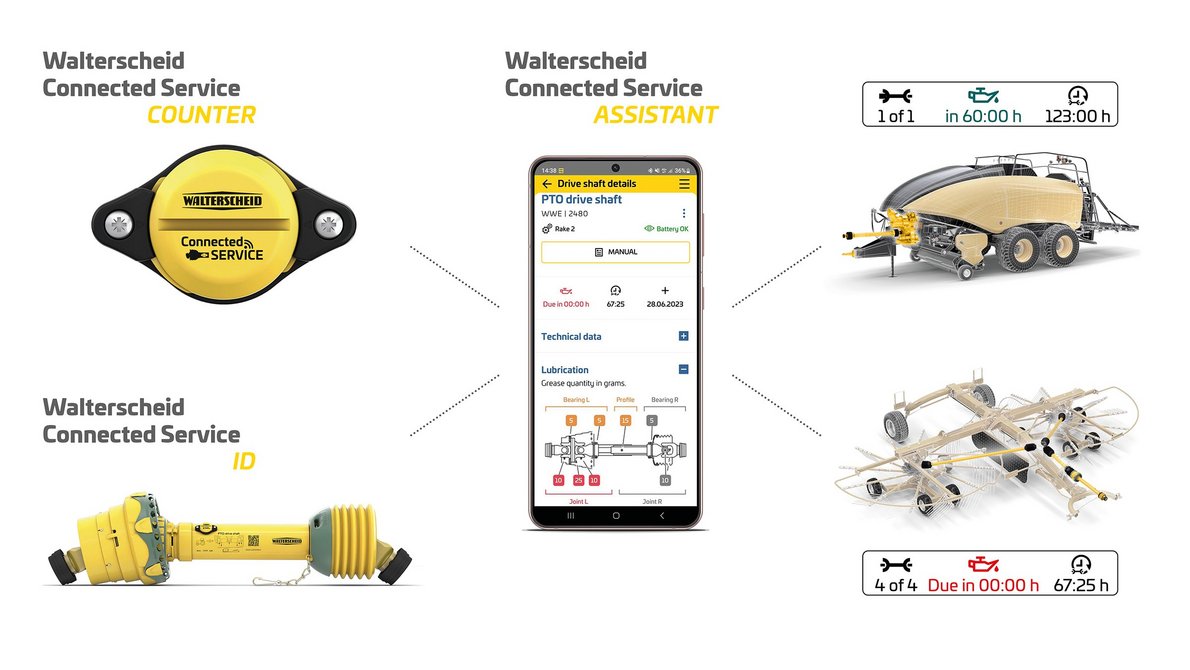

Walterscheid GmbH

Walterscheid Connected Service Counter

Previous hour meters are based solely on the time the agricultural machine is in motion. No distinction is made between actual workload and pure driving time which can lead to non-optimal maintenance times. The Walterscheid Connected Service Counter is the first operating hours counter that not only measures the operating hours of agricultural machinery, but also those of PTO drive shafts. This makes it possible for the first time to carry out operating hour-based maintenance work based on the actual utilisation of the machine. Additionally, Walterscheid PTO drive shafts can be precisely identified by the included WCS ID, allowing the exact lubrication intervals to be determined. The associated app “WCS Assistant” actively notifies about upcoming maintenance work via push message.

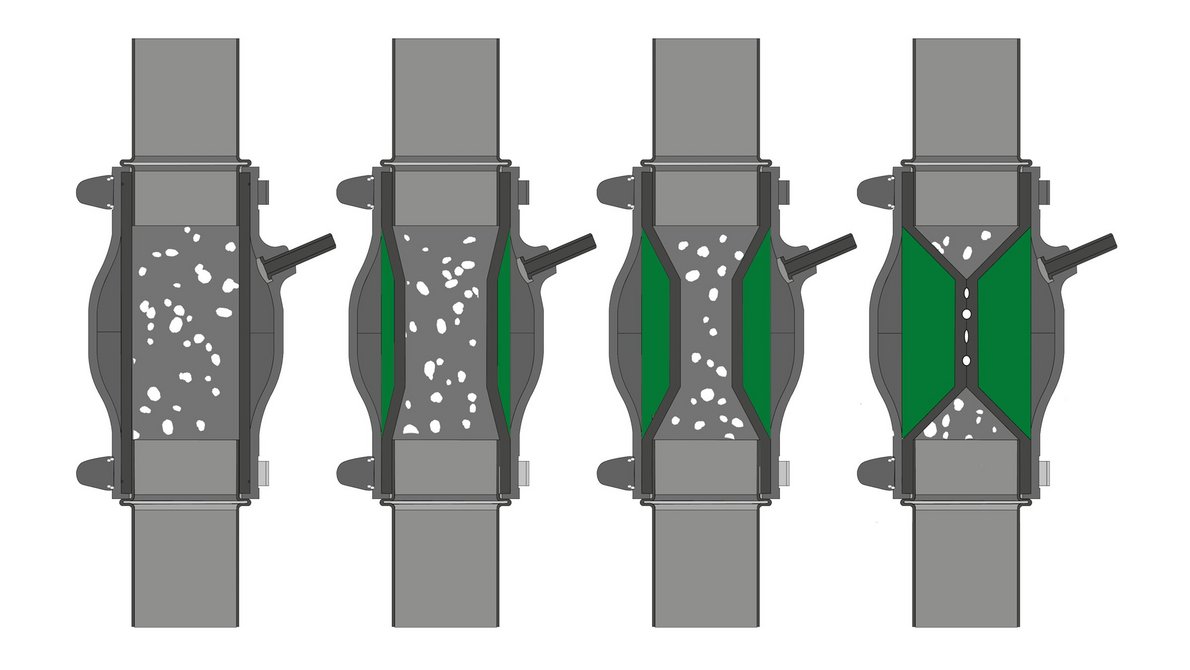

Zunhammer GmbH

FLUSTO

Pneumatic valves for shut-off, regulation and dosing of liquid manure already exist. They are mainly used to shut off the corresponding number of hoses based on an ISOBUS control and typically operate by inflating an internal balloon or similar element. The pneumatic FLUSTO valves from Zunhammer GmbH with their all-new structure are designed for a more fast and uncomplicated interruption of the flow of liquid manure to the outlets in a fully automated process without disturbing the manure flow when open. Unlike conventional valves no interfering components can be found within. Instead, a separate elastic black liquid manure hose can be compressed pneumatically by applying air pressure into the transparent housing of the valves. Due to the different structure, the FLUSTO valves offer a space-saving design, while the transparency housing is a big advantage in terms of maintenance and troubleshooting.