Winners 2023

SYSTEMS & COMPONENTS Trophy

With this trophy, which has now been awarded for the third time, the DLG (German Agricultural Society) recognizes not only the inventive spirit of the supplier industry but also the important contribution to agricultural machinery.

From the shortlist of 21 nominated innovations, the jury, consisting of development engineers from the agricultural machinery industry, selected the final winners:

AGREENCULTURE (Hall 7, Stand A20)

AGCbox

Nowadays, most autonomous machines are equipped with bumpers, to stop them in the event of collision. Some use LiDAR, radar, or sensor fusion to scan the environment and stop the machine if necessary. These components are well designed to avoid collisions, but they can never prevent a robot from ending up in a high-risk area, such as a road bordering a field. Known solutions such as boundary wires or physical limits are not applicable to farming in large agricultural areas.

The AGCbox of AGREENCULTURE now is the first GNSS-based system that precisely locates the machine and detect when it leaves its work area. Safencing is the world’s first certified geofencing system for off-road applications that fully complies with the Machine Directive 2006/42/CE. With this Safencing function, the AGCbox makes robots truly autonomous and thus overcomes the previous methods of supervision that go against all advantages of robotics.

BONDIOLI & PAVESI GmbH Deutschland (Hall 15, Stand E 28)

E.D.I. (Electronic Data Interchange) Driveshaft

It is a fine art to use agricultural machinery as productively as possible without overloading it or causing damage through high and frequent load peaks.

With Bondioli & Pavesi’s EDI PTO driveshafts farmers will be provided with real time information on the tractor dashboard regarding driveshaft’s status, the power absorbed by the implement, and predictive maintenance. The sensor system includes information on torque, speed, axial force as well as vibrations and monitors the degree of overlap of the two PTO shaft halves. This gives the possibility of optimizing productivity and maintenance, reducing costs and time of breakdown. If coupled with a self-driving tractor without operator it provides info and warnings to fleet manager.

Zunhammer GmbH (Hall 23, Stand B33)

FLUSTO

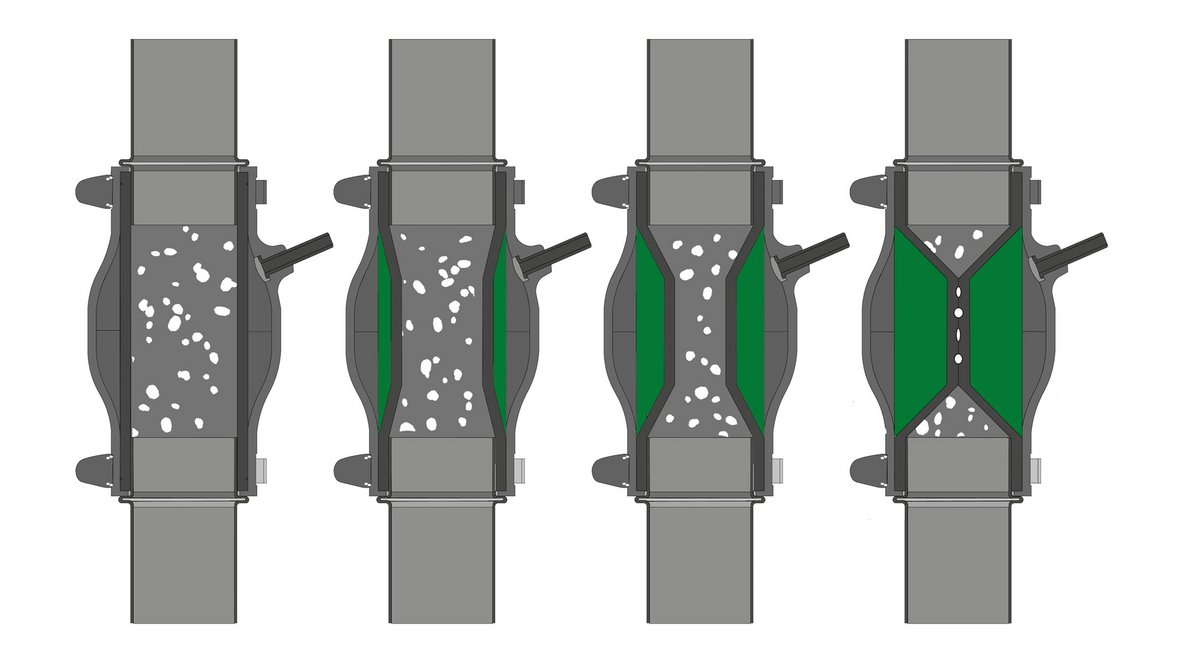

Pneumatic valves for shut-off, regulation and dosing of liquid manure already exist. They are mainly used to shut off the corresponding number of hoses based on an ISOBUS control and typically operate by inflating an internal balloon or similar element.

The pneumatic FLUSTO valves from Zunhammer GmbH with their all-new structure are designed for a more fast and uncomplicated interruption of the flow of liquid manure to the outlets in a fully automated process without disturbing the manure flow when open. Unlike conventional valves no interfering components can be found within. Instead, a separate elastic black liquid manure hose can be compressed pneumatically by applying air pressure into the transparent housing of the valves. Due to the different structure, the FLUSTO valves offer a space-saving design, while the transparency housing is a big advantage in terms of maintenance and troubleshooting.