List of nominees 2025

SYSTEMS & COMPONENTS Trophy

As part of AGRITECHNICA , the DLG awards the "SYSTEMS & COMPONENTS Trophy - Engineers' Choice" for components and systems. The award recognises the importance and innovative strength of the agricultural machinery supply industry.

The DLG has now announced the shortlist of 16 nominated innovations for the award, from which the winners of the Trophy will be selected in a second round by a jury of development engineers from the agricultural machinery manufacturers exhibiting at AGRITECHNICA.

The award ceremony for the winners will take place on 9 November 2025 at the SYSTEMS & COMPONENTS Expert Stage (Hall 17, H02).

Nominees 2025

Bosch Rexroth AG

Rexroth MPR Performance Motor

Hall 16 | Stand A05

Subject area 05 | Hydraulics

A radial piston motor is a hydraulic drive component that converts hydraulic pressure into mechanical energy. After a prolonged period of stagnation in development, OEM requirements have risen sharply in recent years in terms of both potential performance data and size and weight.

The MPR Performance Motor from Bosch Rexroth is a new-generation radial piston motor developed for the requirements of demanding agricultural vehicles with low speeds and high torque. The hydraulic motor is up to 30% shorter and 10% lighter than the previous generation and offers 27% more traction and 25% higher maximum speed. This increase in efficiency and flexibility leads to significant fuel savings and simplified machine designs. Seamless integration into a hydrostatic drive control system with BODAS drive and eDA software further serve to increase performance and efficiency. Added to this are a simple design with 25% fewer components and reduced maintenance requirements due to the design.

All in all, the MPR Performance Motor from Bosch Rexroth is a powerful, affordable motor that is manufactured in Europe with industry-leading delivery times and is characterized by its excellent responsiveness to customer needs.

Bosch Rexroth AG

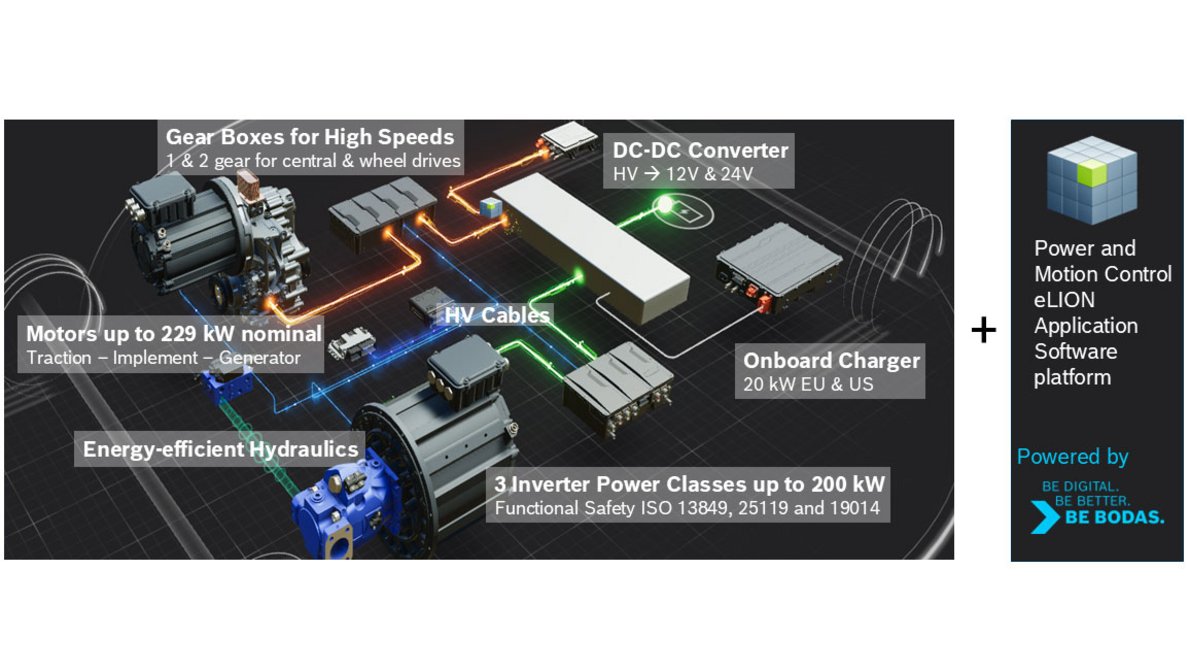

Bosch Rexroth Power and Motion Control eLION Platform

Hall 16 | Stand A05

Subject area 07 | Drivetrain technologies

Until now, integrating electric drives into agricultural machinery required a customized software approach—a time-consuming and resource-intensive process due to the necessary specifications and implementation.

The eLION Power and Motion Control Software Platform now significantly accelerates and increases the flexibility of this development step. Consisting of inverters, motors, onboard chargers, and DC-DC converters that can be flexibly combined, the eLION portfolio enables the electrification of many applications. The Power and Motion Control eLION control software platform enables the combination of three platforms: BODAS Power Control PCL for controlling the high-voltage system and energy management, BODAS-Drive eDA for controlling the traction drive, and BODAS Pump Drive Control eOC for controlling the pump drive, in order to enable noise- and efficiency-optimized operation. This results in lower fossil energy consumption and lower noise emissions, thus protecting the environment.

The eLION Power and Motion Control Software Platform thus enables fast and flexible electrification of agricultural machinery and vehicles.

CLAAS E-Systems GmbH

MK5 Stereo Camera

Hall 15 | Stand F15

Subject area 06 | Vehicle Electronics

Stereo cameras have been used for some time now to examine the environment and control mobile machines, e.g., in row crops. However, the necessary evaluation of the camera data often still has to be performed on the machine's central computer. This, along with the implementation of corresponding algorithms, regularly poses a challenge for OEMs.

The MK5 stereo camera from Claas now combines for the first time the ability to make complex calculalations complex requirements with the durability and robustness required for the particularly high loads in the agricultural environment in a complete system. In addition to analog video transmission and CAN communication, the camera also offers the option of providing communication and digital video via a BroadR-Reach Ethernet connection, a standard well known in the automotive industry, enabling future-proof use in both current and future machine architectures. The system's high computing capacity allows even highly complex computing operations to be performed directly in the camera. The data can then be provided in a wide variety of data output formats, eliminating the need for an external processor unit. This opens up completely new application possibilities in agricultural technology.

The Claas MK5 stereo camera thus represents an important innovation for the future of 3D image-based environment detection and control of mobile machines in agriculture.

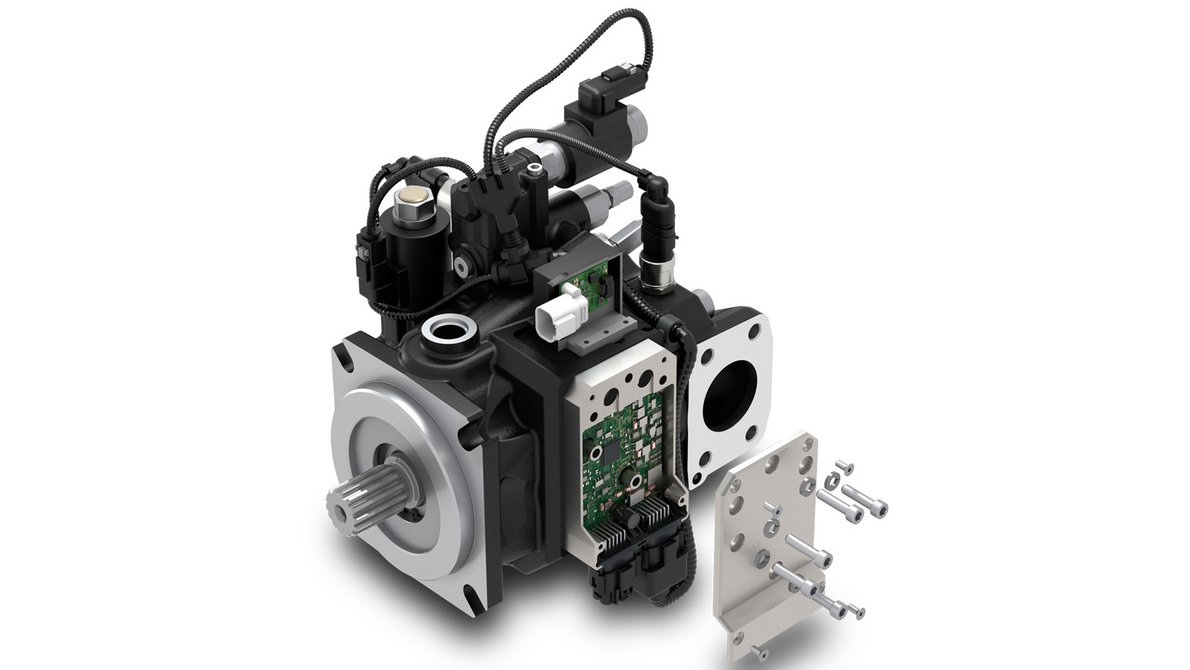

Casappa S.p.A.

Casappa Smart Data System

Hall 16 | Stand B11

Subject area 05 | Hydraulics

Axial piston pumps are generally characterized by their already very high efficiency. However, there is potential for improvement through precise control of the volume flow and thus optimized adaptation of the overall system to different load conditions, as well as improvements in maintenance intervals and machine running times.

Casappa is now taking the variable displacement axial piston pumps commonly used here to a new level with its Smart Data System. Mounted on the piston pumps of the MVPS series, the system's innovative integration of embedded electronics and miniaturized sensors not only enables continuous monitoring of important hydraulic data, but also allows the amount of the load to be analyzed. This allows anomalies to be detected at an early stage, and failures to be reliably predicted and displayed both in the machine control system itself and externally via the cloud. Particularly noteworthy is the fluid analysis sensor developed in collaboration with Sanchip, which can be used to monitor oil quality online.

The direct integration of all electronic components and sensors eliminates the need for external cabling and distributed sensors, simplifies the machine layout, reduces costs, and represents a significant advance over the previous state of the art.

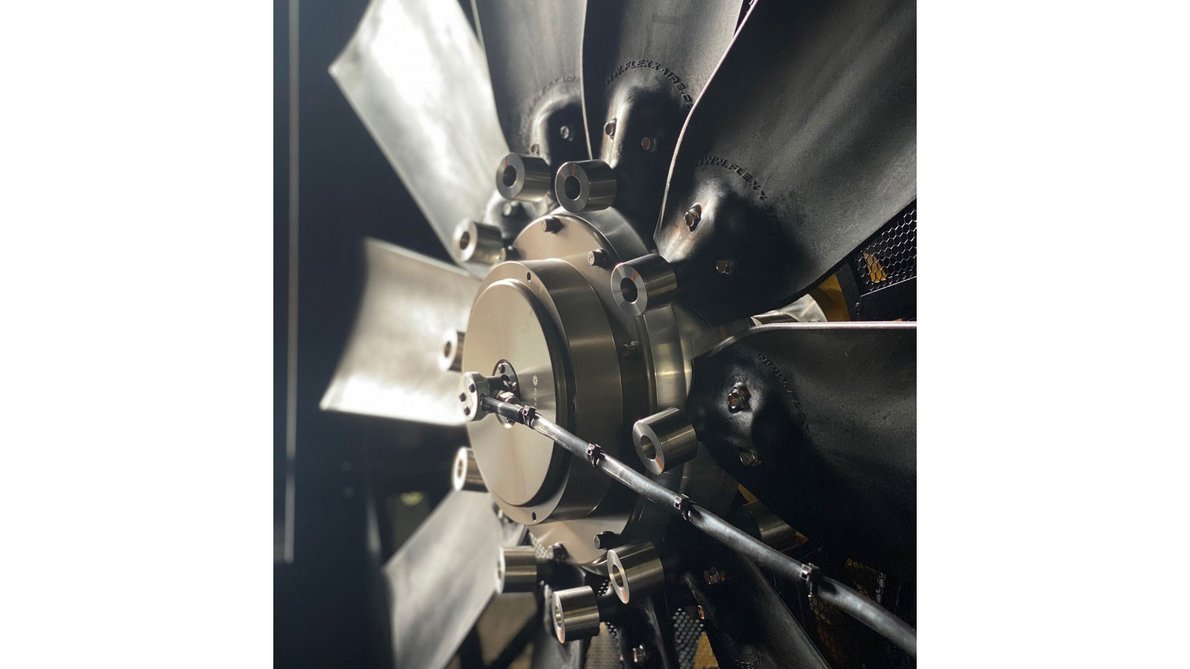

Flexxaire Inc.

Flexxaire Infinite Variable Pitch Fan

Hall 15 | Stand J04

Subject area 03 | Spare and replacement parts

At full cooling capacity, the drive power for the fan of the engine cooling system can account for several percent of the tractor's rated power, especially with fixed or only coarsely graded fan speeds. Optimizing the radiator ventilation to the actual engine power required and thus the waste heat generated therefore offers considerable fuel savings potential.

The Infinite Variable Pitch (IVP) fan from Flexxaire is the first fan system that can automatically adjust the angle of attack of the fan blades in real time to the machine parameters based on the data available on the CAN bus. This ensures optimal airflow, lower fuel consumption, and quieter operation. The system is also capable of reversing direction to remove debris from the cooling system. This maximizes cooling performance and machine uptime in demanding environments. The IVP fan system integrates seamlessly with modern engine controls, offering both performance optimization and reduced maintenance in a single, intelligent component.

By combining available motor and machine load data with adaptive fan control and automated cooling and cleaning, the Flexxaire Infinite Variable Pitch Fan can further improve machine efficiency. This reduces operating costs and increases machine service life while also increasing operating times.

HYDAC International GmbH

SUSTAINMICRON® - the new standard filter element technology

Hall 17 | Stand H15

Subject area 03 | Spare and replacement parts

Abrasion and foreign particles are the natural enemies of every hydraulic system and must be removed using appropriate filter systems. To this end, a constant volume flow is continuously passed through the hydraulic oil filter. Measurable via the differential pressure, i.e., the pressure loss in the hydraulic oil filter, more and more energy must be expended to maintain this volume flow as the filter becomes increasingly contaminated.

The universal SUSTAINMICRON filter element from Hydac sets a new standard here. Thanks to the special filter design, the differential pressure caused by the oil filter can be reduced by up to 30% without compromising filter performance as was previously the case. A new outer shell made of special two-component fibers significantly reduces the risk of electrostatic discharge, which not only leads to a reduction in system failures caused by this, but also to increased oil stability and thus longer maintenance intervals. The filter system can be used independently of the drive technology wherever first-class filtration and high efficiency are required.

Due to its high efficiency gains and significant optimization of electrostatic behavior, the Hydac SUSTAINMICRON hydraulic oil filter element represents a significant innovation.

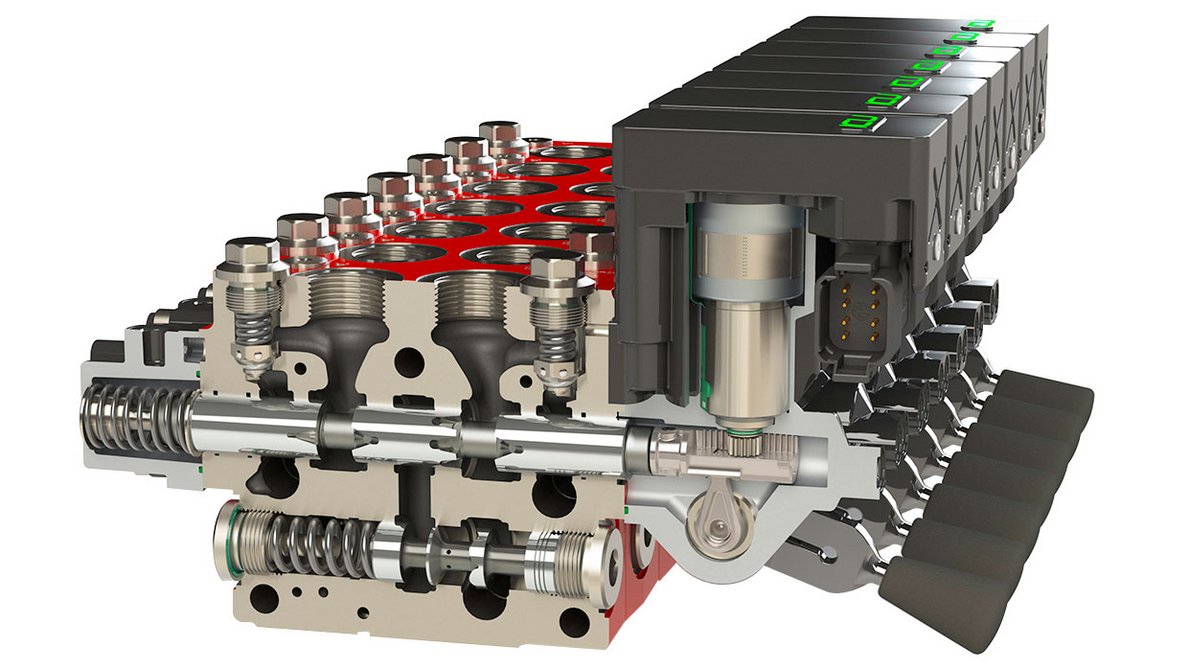

HYDAC International GmbH

HYDAC LX Load-Sensing valves with Intelligent Control Unit (ICU)

Hall 17 | Stand H15

Subject area 05 | Hydraulics

A hydraulic distributor is a component that regulates the flow of fluid between pumps and actuators and other components in a hydraulic system. The distributor is therefore a core component of a mobile machine, whose quality and functionality significantly determine the performance of the entire vehicle.

The new electromechanical HYDAC LX load sensing valves with intelligent control unit (ICU) offer several important advantages over most electrohydraulic systems. For example, the system operates without control oil and is therefore independent of the stability of the pressure oil supply, temperature, and oil viscosity. The HYDAC LX load sensing valves with intelligent control unit also operate without hysteresis, i.e., they are repeatable and have no reaction time losses. Compared to electrohydraulic actuation, energy consumption is significantly reduced as there are no losses due to the pilot oil circuit. In addition, the ICU transforms the LX valves into an intelligent system. The valve block receives its SET coil positions from the control unit via the CAN bus and adjusts them in no time at all.

The HYDAC LX load sensing valves with intelligent control unit (ICU) thus offer high precision, TÜV-certified safety, and reliability even under the harshest environmental conditions, while at the same time improving efficiency.

igus GmbH

ReBeL Cobot

Hall 16 | Stand E11

Subject area 06 | Vehicle Electronics

High-precision and repetitive tasks such as weeding or harvesting of fruit are often physically demanding and are still frequently carried out manually, requiring a large workforce.

With the ReBeL Cobot, igus has now introduced an articulated arm robot weighing only 8 kg, which, thanks to its particularly simple operation and low price, makes entry into automation in agriculture easier and more accessible than ever before. Equipped with sensors and grippers, it is ideal for tasks such as fruit harvesting, sowing, or indoor farming. Depending on the application, the robot arm can be equipped with various sensors such as cameras or work tools. In addition, it offers simple, user-friendly, and practical programming options. Using a free, license-free software test environment, users can test any kinematics and thus find out before purchasing whether the planned application can be realized with the ReBeL.

Mounted on a suitable autonomous chassis, the igus ReBeL Cobot can, for example, reduce the use of labor during harvesting and at the same time enable a higher number of harvest passes, which leads to greater efficiency and less strain on harvesting personnel.

Mach, Inc.

RadX

Hall 17 | Stand C05

Subject area 06 | Vehicle Electronics

As technology advances, more and more sensors are being used in agricultural machinery and tractors to improve their control. The raw data from these sensors usually is processed centrally, which places high demands on computing power and data analysis. OEMs repeatedly struggle with difficulties in evaluating sensor data and programming efficient evaluation algorithms.

Mach's RadX radar device is the first system of its kind to not only bring true phased array technology to agriculture, construction, mining, and land management, but also to process the captured signals internally and make them available in the OEM's system architecture. The system uses electronically controlled beams and adaptive beamforming for high-resolution 3D detection in real time, eliminating the need for moving parts.

RadX is able to distinguish between soil, crop residues, and vegetation while simultaneously mapping the terrain surface, making the sensor particularly interesting for use in depth control of tillage, planting, and seed drills, as well as in terrain guidance for combine harvester headers. An evaluation of the quality of work behind the machine is also conceivable.

Mach's RadX system thus represents an important innovation for the future of 3D image-based environment detection and control of mobile machines in agriculture.

MOBA Mobile Automation AG

AGRI-SONIC

Hall 17 | Stand B18

Subject area 06 | Vehicle Electronics

Precise depth control of soil cultivation machines is particularly challenging because soil conditions are constantly changing. Automating the depth control process depends entirely on detecting the soil surface.

Moba's Agri-Sonic solves this problem with the help of a particularly advanced ultrasonic sensor. Ultrasonic sensors continuously emit ultrasonic waves and detect their reflections from surfaces. The Agri-Sonic detects not only the first echo, but also several different reflection patterns. This allows the actual position of the soil surface to be filtered out and determined, even under vegetation and crop residues. The Agri-Sonic's integrated electronics output precise depth values via the CAN bus in real time, which are displayed directly to the operator on a display in the cab or can be used to automate depth control.

The Agri-Sonic ultrasonic sensor thus significantly improves the options of modern soil cultivation, where a precise and shallow working depth is essential for maintaining soil structure and improving efficiency. Every additional centimeter of depth increases fuel consumption and accelerates component wear.

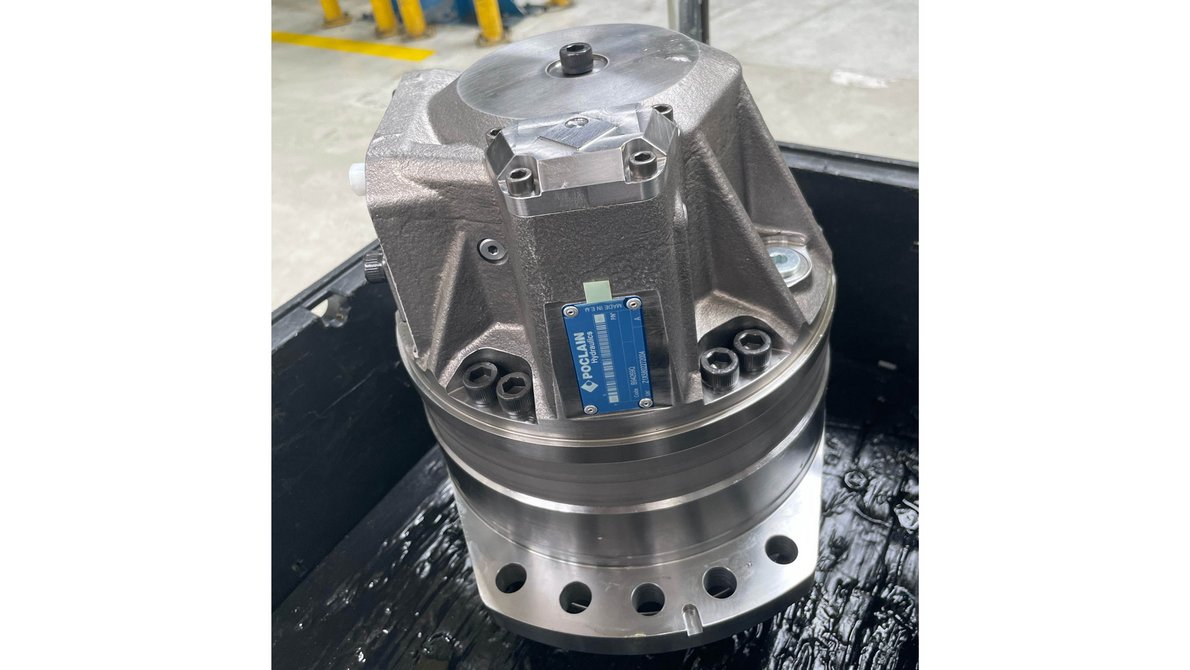

POCLAIN

MHD09 – The Dual technology

Hall 16 | Stand B18

Subject area 05 | Hydraulics

Direct drive motors are known for working extremely efficiently at low speeds, but in some high-performance applications there are limitations in terms of service life and internal pressure losses.

Poclain has now developed a new generation of radial piston motors with MHD09 – The Dual technology, which enables continuous use of all pistons. Without having to deactivate pistons even when underutilized, without requiring additional parts and materials, and without affecting the compactness and size of the motor, Poclain has thus been able to reduce the total pressure contact by at least four times at high power.

This reduces the total contact pressure at high power by at least four times compared to the current solution, without requiring additional parts and materials. This improvement is achieved without affecting the compactness and size of the motor. In addition, Poclain is introducing a new technology to completely eliminate internal recirculation: A vacuum is created within the motor's lines and the pressure is reduced to almost 0 bar, which significantly reduces internal losses and enables higher speeds.

With its innovative MHD – The Dual technology, Poclain is offering OEMs a significant optimization in the field of high-torque, low-speed motors.

RAFI GmbH & Co. KG

SAFETY TOUCH

Hall 17 | Stand B29

Subject area 06 | Vehicle Electronics

Touchscreens are now very widespread, not least because of their intuitive operation and the possibility of placing individual controls where they are sensibly arranged and ergonomically accessible. However, due to their design, touchscreens are prone to operating errors, such as accidental touches, which has previously ruled them out for the operation of safety-critical functions.

Rafi's Safety Touch now closes this gap and, for the first time, enables the input of safety-critical functions directly on the touchscreen, which leads to greater design freedom in terms of ergonomics and greater operational efficiency while complying with strict safety standards. Safety Touch uses touch detection with simultaneous measurement of the actuation force to ensure intentional input and prevent accidental activation of the safety-critical function. In addition, optical and electrical monitoring as well as content integrity checks are used to ensure that the correct screen content is displayed. Due to the safety level achieved, Safety Touch can be used to display safety-related display elements and to switch safety-critical functions that would otherwise require other hardware, such as an electromechanical control system.

Safety Touch eliminates the need for special input elements such as push buttons, which were necessary in previous user interfaces for safety-related actions. This allows for greater flexibility, improved ergonomics, and optimized workflows without compromising safety.

SICK AG

multiScan100-S

Hall 17 | Stand B21

Subject area 06 | Vehicle Electronics

As development progressed and the need to control agricultural and construction machinery as well as tractors more effectively and efficiently grew, more and more sensors were installed. With the current state of technology, the raw data of each and every sensor is transmitted to the central machine computer and processed there. Evaluating the sensor data and programming evaluation algorithms regularly presents OEMs with difficulties.

With the multiScan100-S, Sick is introducing the first 3D LiDAR sensor that integrates the detection of the environment of mobile machines, the recognition of possible obstacles or endangered persons in the vicinity, and the provision of the appropriate safety function for the situation in a complete system. This combination of hardware and software performance makes the multiScan100-S a true all-rounder. The robust measurement technology and IP69K-protected housing ensure high availability in harsh environments such as those commonly found in agriculture and construction. The 3D LiDAR sensor is certified according to ISO 13849-1 and IEC/TS 62998-1 standards for safety-related outdoor use and operates very reliably even in environments with poor lighting conditions or high levels of dirt and dust.

Both in terms of machine safety and the further processing of the sensor data collected, the Sick multiScan100-S represents an important innovation, also with a view to the future autonomous operation of mobile machines in the agricultural and construction industries.

SICK AG

Visionary AI-Assist

Hall 17 | Stand B21

Subject area 06 | Vehicle Electronics

Stereo cameras have been used for some time now in environment detection and the control of mobile machines. The 3D images captured can also be used for obstacle detection and collision avoidance, but the development and integration of suitable evaluation algorithms remains a challenging task, especially for OEMs.

With Visionary AI-Assist, Sick is now offering a robust, 3D camera-based solution for safe collision avoidance in mobile machines for the first time. AI integrated into the camera system detects obstacles in the environment and determines the distance to the respective object. Because even untrained objects are reliably detected, false alarms are rare. This reduces the burden on the operator and increases safety and productivity. The modular edge computing design eliminates the need for external processing hardware, reducing system costs and complexity. A customizable field of view, various interfaces for seamless integration into the system architecture, and a robust design for tough outdoor agricultural applications offer OEMs great benefits, while the option of a live video stream supports the operator, enabling more sustainable and energy-efficient field operations.

Visionary AI-Assist thus is a groundbreaking technology for 3D image-based environment recognition that significantly improves the control and safety of mobile machines in agriculture.

STW - Sensor-Technik Wiedemann GmbH

Safety Assist

Hall 17 | Stand D12

Subject area 06 | Vehicle Electronics

In cooperation with driveblocks GmbH

Blind spots around agricultural machinery pose a particular danger to humans and animals because they cannot be seen by the operator. Surround-view systems with multiple cameras can significantly reduce these blind spots, thereby ensuring greater safety.

With Safety Assist, STW – Sensor-Technik Wiedemann is now offering the first solution for software-defined vehicles, i.e., primarily electronically controlled and thus software-defined vehicles in agriculture. The system offers adaptable surround view with person detection and allows switching to plug-and-play cameras for a combination of environmental and process monitoring. In addition, it enables automatic machine parameterization based on the attachment used and dynamically positioned cameras. The innovation of Safety Assist results from the combination of functions that were previously independent of each other in the state of the art, significantly reducing the development, manufacture, maintenance, or testing of electrical and electronic components and systems. In addition to safety functions such as person detection, the system can be used to automate driving functions, simplify machine handling, and develop and implement additional assistance functions.

Safety Assist thus integrates a wide variety of sensor-based and other ECU functions into a comprehensive, safety-oriented complete system for the first time, combining them with the ability to support and update the AI online throughout the entire machine life cycle.

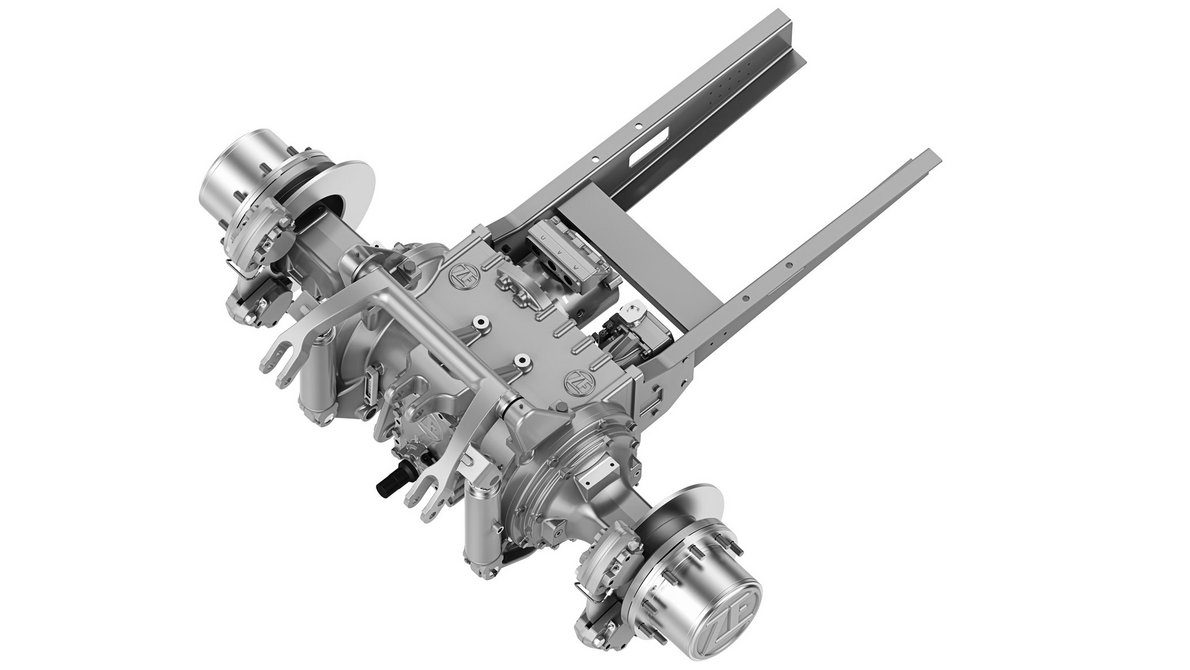

ZF Group

ZF eTD

Hall 15 | Stand C06

Subject area 07 | Drivetrain technologies

In current electric tractors, the combustion engine has generally been replaced by an electric motor with a reduction gear, without affecting the familiar and proven hydrostatic power-split CVT drivetrain.

The electric TerraDrive (eTD) from ZF Friedrichshafen takes a different, completely new approach: The modular, highly integrated electric axle system combines traction, PTO, and hydraulics in a compact design for tractors up to 100 kW. This not only enables emission-free operation without any loss of power, but also means that central transmissions, hydrostatic units, clutches, and hydraulic systems can be partially eliminated or replaced by a dual electric powertrain with energy recovery and an optimized design for maximum efficiency and flexibility during installation. At the heart of the eTD is a highly integrated electric drive unit with two oil-cooled electric motors – one for the drive, the other for auxiliary drives. The change in the basic design concept creates space for batteries or hydrogen tanks, which can significantly increase range and operating time. The S&C Trophy commission points out that this not only applies to classic tractor applications, but above all can also be transferred to other machines.

The eTD thus represents a scalable, future-proof solution for emission-free agriculture without compromising on performance or functionality.